In a recent video interview (below) from SPEZI, Gary Solomon interviewed Alligt’s Leo Visscher about all sorts of his products, but a very interesting part of the interview starts at minute 5:35 and concerns the development of a new velomobile, or as Leo calls it, a velocar, but one that will be produced using rotmolding technology. We know the technology from the Australian Trisled’s Rotovelo velomobile and also their new racing machine called Skyhawk, which we reported on recently. It’s a technology that creates durable plastic large-scale elements that can be produced quite quickly and can significantly reduce the cost of production, especially if a lot of them were produced. Unlike Trisled and their rotomolding velomobiles, which have an internal frame, Leo plans to make the body to be self-supporting.

So what do we know today?

Alligt is working on a completely new Alleweder body with a quad layout. It is going to be a self-supporting structure made from rotomolded thermoplastic. They aim to offer this to manufacturers starting in 2026. A complete kit is not currently planned, but the body will be made available to other manufacturers and possibly also to dedicated self-builders. Based on their experience with the Alleweder A4, many people are capable of building a velomobile themselves, but Alligt does not intend to sell a full kit directly, partly due to liability concerns.

This body is intended as the successor to the A4, A6, and Sunrider—but only as a body shell, not a complete vehicle. They are following a similar approach as with the A4: Alligt will sell the body, and others can develop and produce the kits.

Current progress and upcoming steps

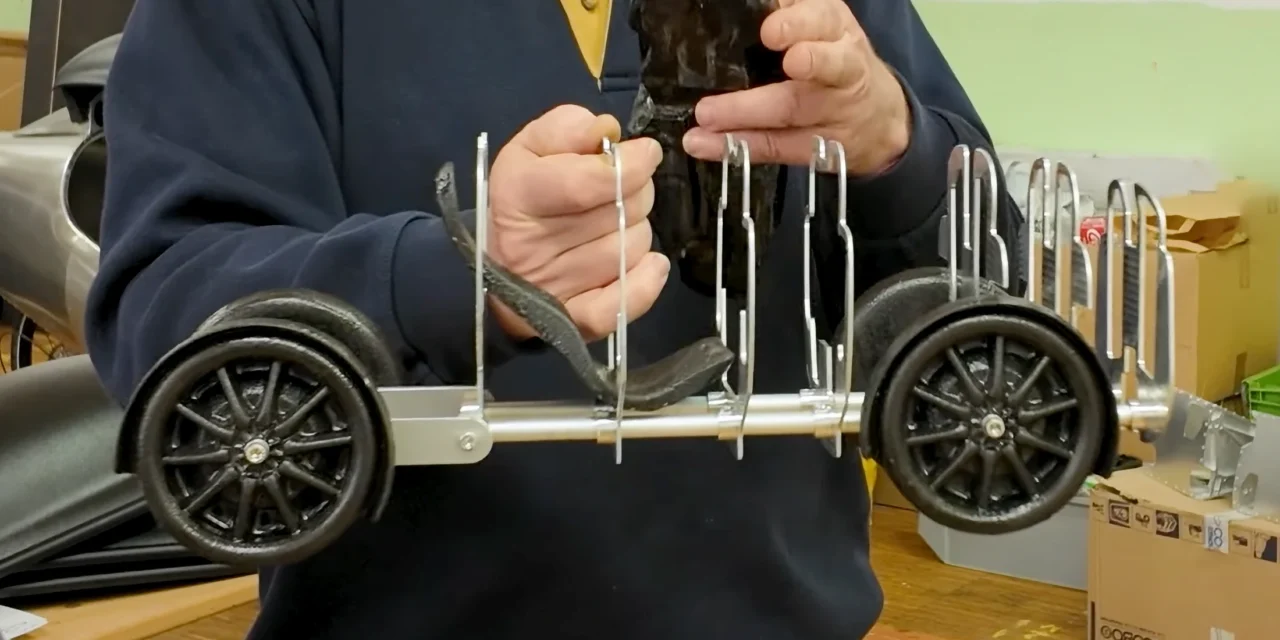

They have scanned a Sunrider velomobile they produce on a wheeled frame to create a 3D model. In this model, the interior, seat, and exterior have been integrated into a single unit. The seat design is a hybrid of their existing models and the Podbike seat. This design is already fairly final.

Alligt has already produced the roof and all four mudguards, which were offered for sale at SPEZI 2025.

The front wheel arches are approximately 15 cm / 6″ deep, allowing for a tight turning radius when combined with the right steering system.

Dimensions and construction

The velomobile will be about 80 cm / 31.5″ wide.

The structure must be heavy enough not to be blown away by the wind, yet still significantly lighter than a car. The estimated minimum weight is around 60 kg / 132 lbs.

Drive and suspension options

Alligt anticipates that the vehicle will be used with electric assistance. There will be sufficient space to integrate a mid-drive motor or hub motors. It will also be possible to install a pedal generator.

A full chain-driven transmission is not required but can be added. This choice is left to the builder or manufacturer. The roof and mudguards are designed as separate components, ensuring good splash protection and greater design flexibility.

Material and sustainability

The body will be made of 100% recyclable thermoplastic with walls approximately 4 mm thick.. The downside of this material is that it is not easy to paint or apply stickers to—a trade-off that has to be accepted. However, the material usually can be of different colors.

The goal is to produce the mold in 2026 and deliver the first body shells that same year. Whether Alligt will also offer kits or complete vehicles will depend on interest from the market.

Safety

A self-supporting plastic body offers passive safety benefits. The front section can act as a crumple zone, and the plastic has slight elasticity. The roof and side structures also help improve visibility in traffic.

User size compatibility

The Alleweder A10 will be suitable for riders between approximately 170 and 200 cm / 5′ 7″ to 6′ 7″ in height with a normal stature.

More information here: https://www.alligt.nl/alleweder-a10/

As mentioned, the interesting part starts at minute 5:35 of the video.