This trike was made by a famous Czech recumbent homebuilder Jirka Hebeda who has built several recumbent bikes already and is working on some others. You can read more about the process of building it and how it rides here under.

SnowZombie is a 20/26 delta trike with a 2-wheel drive. It was created to satisfy the desire to leave the car at home and enjoy going to work on human power regardless of slippery winter conditions.

The design is based on following order of priorities:

1. Recumbent for comfort =>trike to get over ice without crashing.

2. Enough traction to get through up to 15cm of snow if necessary and over any slippery surface, even uphill => 2-wheel drive and low gearing.

3. Low resistance if possible and get over 15cm high obstacle without problems => large and/or suspended wheels

4. Minimize delta configuration stability disadvantage => lowest possible seating and room to move upper body sideways when cornering

5. Free pedaling in all steering positions => zero overlap of front wheel with feet

6. Fit through narrow spaces easier than most tadpole trikes.

7. Easy and fast build in a home workshop with some machining but no welding => bolted aluminum frame

The resulting design is fairly narrow tracked (66cm) and very long (260cm) delta trike with two driven 26” wheels in the back, rider almost in front of them in a seat just 22cm above ground and a suspended 20” wheel in front of the rider. The minimum ground clearance is about 15-16cm depending on tires. The spot most likely to hit the ground – frame under the seat – is reinforced enough to withstand hitting a large boulder. Main backbone tube goes horizontal from there to the rear end protecting the derailleur from hitting the ground.

SnowZombie was built in just one month, between 4th December and 29th December 2010 after several months of thinking, drawing, deleting and drawing again and so on. Every part of it is made just functional enough. No cosmetic concerns, no weight saving measures, everything just “that’ll do”.

It is made almost entirely out of aluminum square tubing and bar stock. The main frame is a 50x50x3mm square tube. The joint under the seat is almost full of aluminum inserts milled, drilled and tapped to bolt the main parts of the backbone together. Some milled pieces hold the two head sets.

Rear axle supports are built around the axle itself. That was purchased complete with 4 ball bearings in aluminum block with M8 taps, ready to mount into some frame. So a frame was built to fit it in the simplest possible way and joined to the backbone by two long 20x20x2mm square tubes going along the seat and two perpendicularly to them.

Seat is mounted to the backbone on the lower end and supported by two seat stays against the rear axle on the top end. It was bought as scrap prototype from Azub and so were the handlebars. Leg length is adjusted by sliding the bottom bracket along the frame backbone.

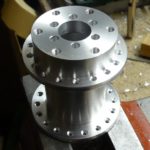

The bought axle had hubs with no brake disc flanges and with inner spline joint to the axle. Therefore they were stripped of their spoke flanges in a lathe, drilled and tapped to receive M6 bolts on both ends. New hubs were turned that fit over the torso of the originals and bolt via those M6 holes. There are two sets. The main ones are bolted from the frame side, hold the brake discs and main rear wheels. There is another pair of secondary hubs that can be mounted from the outside via the other 6 M6 holes and hold second pair of tires. In theory that should have same effect as those expensive 4” tires in snow, however there was never a good opportunity to test this feature yet.

To make it easier to use every day there is also a luggage rack made from some Ikea pot stand.

The rear mudguards are held by a seemingly overbuilt structure. The reason for this is that when space is limited the trike can be parked on its tail standing on this structure.

Overall it weights about 30kg in its basic configuration. Just the diff and rear axles are about 6kg, there are no lightweight components used and the frame was not built to be light either.

The drive system is the most important part of the SnowZombie design.

It has two chains. One runs from conventional MTB chainrings (22-32-42) to an 8-speed 11-32 cassette. The cassette is on an empty MTB hub mounted in front of and higher than the rear wheels axle. That allows for better ground clearance of the rear derailleur but more importantly also for a step-down ration via a second chain. The second chain runs form 15t cog on this hub to a 28t cog on the rear axle. The result is the highest gear is good only for about 25 kph and the lowest lets you fight your way up a steep hill in deep snow.

The rear axle is driven via an open differential. The idea is that simple freewheels would tend to always power the inner wheel in a corner and worsen the natural understeer of a delta trike. The human engine, unlike a car engine, has a very rough, almost intermittent delivery of power. Therefore if one wheel approaches the limit of its traction, it will intermittently slip always for a short time only when the feet have maximum leverage on the cranks. This expectation has proven to be justified and the differential works well. Practically under all conditions the power of the rider is insufficient to make one wheel spin all the time preventing the vehicle from moving. This can only happen if there is no weight on one wheel or one wheel is on ice. And even then the drag in the differential gears and some limited friction of the ice combine to still provide some driving force to the other wheel. And if that is not enough the trike has independent rear brakes the rider can use to block the spinning wheel much like the electronics of a modern SUV do. In a similar fashion one of the brakes can be used together with full power on the pedals to initiate a turn on smooth ice followed by release of the said brake and a nice, long power slide.

The result is that the trike can go through any snow that happened in the Brno area in last two winters with no problems, it can go through mud where it sinks up to its frame, even stop there and get going again, and it is nicely controllable on ice. What used to be an annoying experience is now fun. And when freezing rain happens and pedestrians keep falling every ten steps I can enjoy my daily commute even more than I usually do.

Currently the SnowZombie is about 2000km from its first test ride and it still works. It is a tinkerer’s machine, often in the shop, frequently having some partes repaired or upgraded. The frame makes crazy creaking sounds and all those bolts (over a 100 of them) have to be periodically checked for tightness. Perhaps I will build the same proven design with a welded frame one day to take care of that.

It is however deeply satisfying to always get to work no matter what the weather troughs at you or to occasionally crawl through some offroad trails in a low gear.